Dettagli Prodotto

ANALISI CONSUMO ENERGETICO IMPIANTI ARIA COMPRESSA

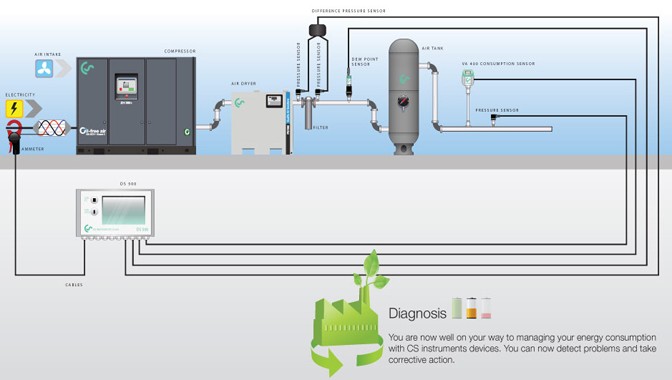

Energy management begins somewhere

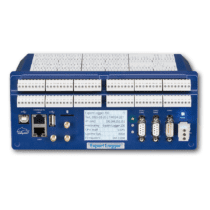

Loss of air in your system leads to extra energy consumption and moisture in your system results in corrosion of your plant. It is not easy to know how well you are doing without measuring. Many industrial plants don't even check whether problems are arising in their system. They simply see the energy bill rise over the years, change parts in a haphazard way. Some simply fail to notice the extra consumption, because it increases slowly over a longer period. The first step towards a healthy and optimised plant for gas- or compressed air is to take the necessary measures. To this end you would require flow sensors, dewpoint sensors, ammeters and preferably software and screen display to help record, interpret and diagnose the system. Whilst it does not optimise your system per se, you have to start somewhere. That somewhere is finding out how you are performing in real numbers, in order to take corrective action on any deficiencies.CS instruments produces devices tailored to this exact task.

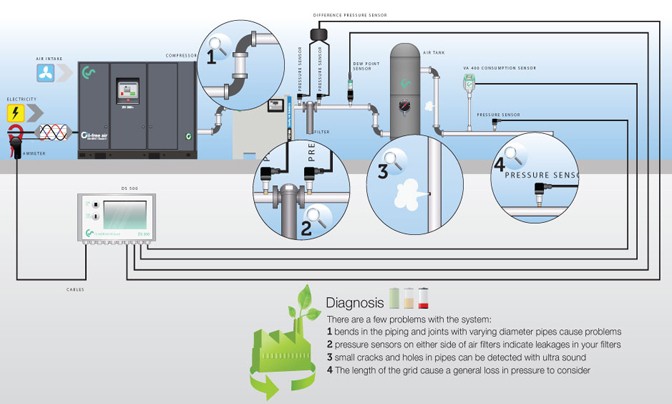

Once you have fitted the measuring devices, it often becomes clear where to take corrective action

As soon as you have fitted the various measuring devices, the apparent waste of energy becomes evident. In the diagram above you will find four examples of perennial problems in compressed air systems. Fixing these problems is your way to improve the profit margin derived from your production. Quite often you can detect the larger problems around bends and joints in piping as well as air filters, or by shortening the entire length of your grid down to what is strictly necessary. After that is done, you can tackle the smaller leaks before they become larger and more evident. Small holes and cracks in piping can be detected quite effectively with ultrasound devices supplied by CS Instruments. Yet other problems show up when the system is under stress and running at full capacity. In turn it suggest it is sensible to measure the system over time and under different loads. For that we offer software to help make sense of the historic data being gathered.

CS instruments produces devices tailored to this exact task.

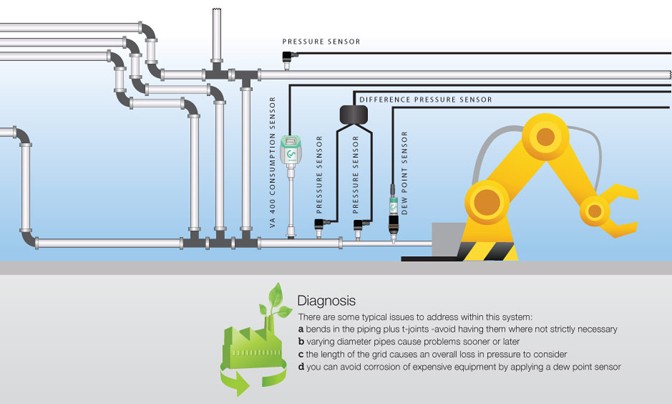

Roll out solutions after pinpointing the hot-spots

Have a closer look on what you've found out in the last steps and transfer the insights onto your whole system. These insights will help you with future plans and enhancements as well as early detection of losses. Most problems are not obvious but all around, like unnecessary bends and t-joints, varying diameter pipes and moisture in the system because aof an unknown dew-pint. Raise awareness for these hot-spots and keep them into mind for future plans and enhancements. Effective use and an optimized grid will help you save money and grow profits - an important point in times where profits shrink and competition grows. CS instruments produces devices tailored to this exact task.

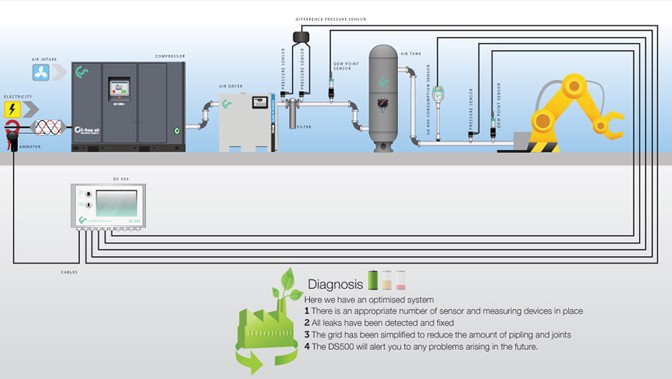

Have a look at your optimized system